So you have developed your strategic mine plan and your mining operation is up and running. Things have changed (as they always do) and now you need to investigate the impact of increasing the capacity of your processing plant after the first three years. This is a familiar scenario, and can be problematic without the right mine planning software. The good news is that there’s an easy way to do this that won’t exhaust your time or energy.

In this short how-to article, we’ll show you how to model a delayed mill expansion for the scenario of a small gold mine using Minemax Scheduler software for integrated strategic mine planning and scheduling.

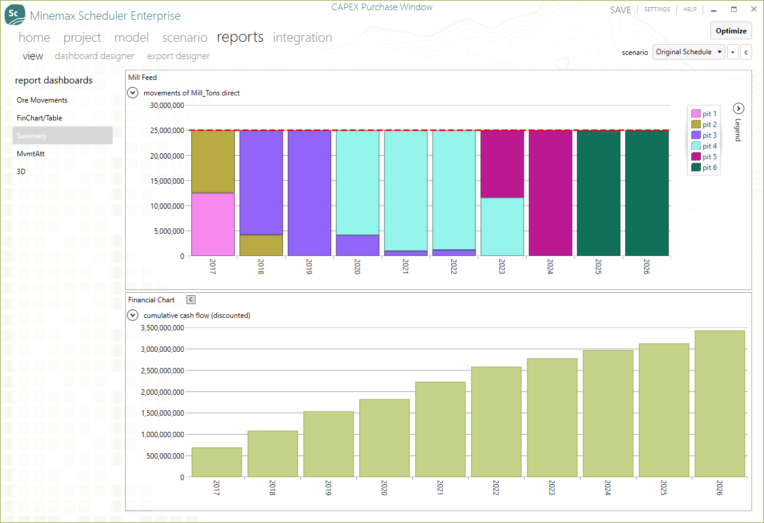

The Schedule before Capex

Let’s begin with the 10-year schedule that maximizes Net Present Value (NPV) while meeting all our mining and processing constraints. We can see in the report below that with a mill feed of 25 million tonnes annually, we can achieve a total NPV of $3,430 million.

Setting up Delayed Capex with Capacity Increase

Now let’s change our model to increase the capacity of the mill by 20 million tonnes. The capacity increase incurs a Capital Expense of $30 million, and can’t start until 2020 (the fourth year) at the earliest.

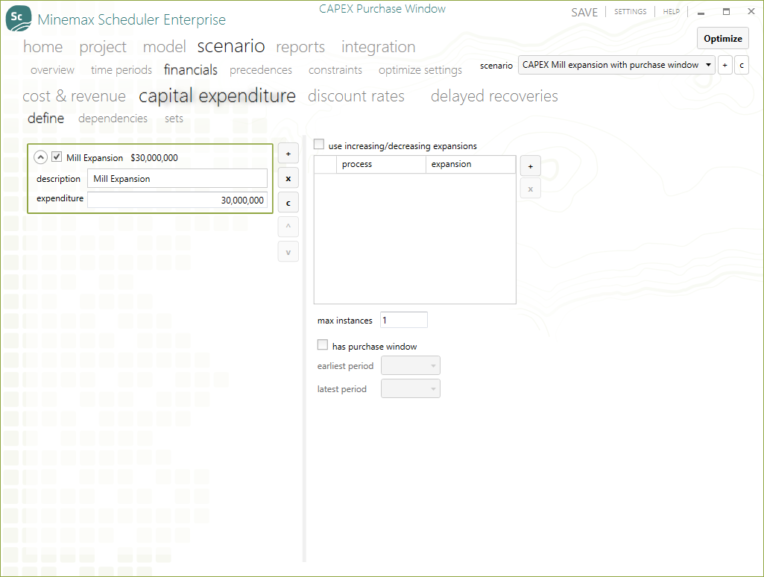

Step 1. Define your CAPEX option

First we go to the scenario > financials > capital expenditure screen and click the plus button to define the name for our Mill Expansion and to enter the cost of $30 million.

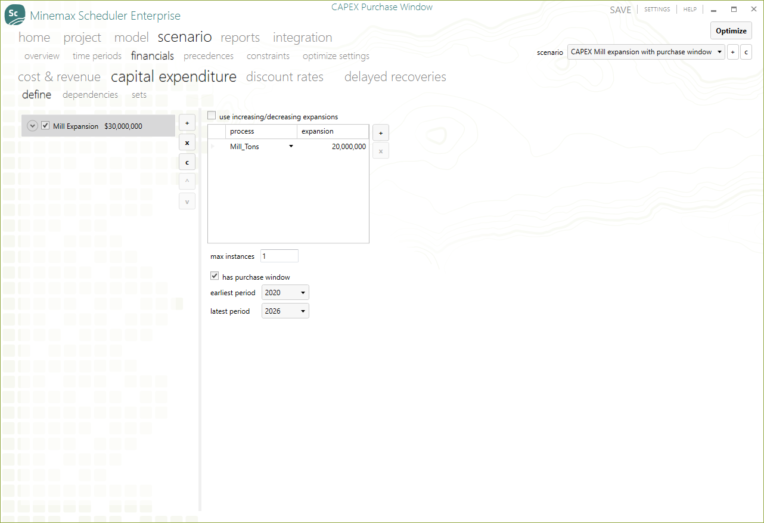

Step 2. Define the expansion associated with your Capex

We click the plus button next to the process/expansion table on the right and select the Mill_Tons process that represents our current mill feed. In the expansion field, we enter 20 million tonnes per year.

Step 3. Define the purchase window

Finally, we check the ‘has purchase window’ checkbox and change the earliest start from ‘2017’ to ‘2020’ to delay the start of the capital expenditure. This is all we need to do before we hit the Optimize button to re-optimize our schedule.

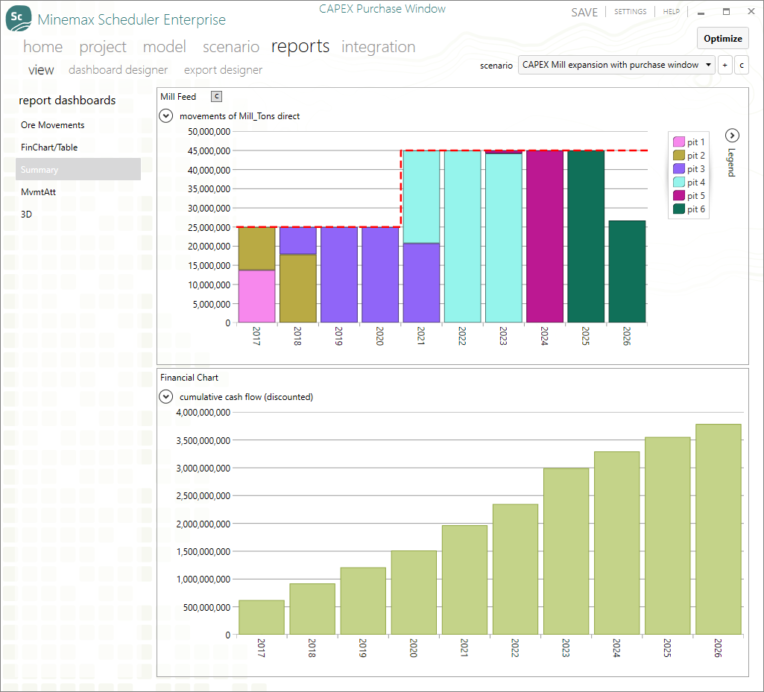

Results

During the optimization, Minemax Scheduler decides whether it’s worthwhile to incur this Capex to increase the processing capacity and, if it is, the optimizer determines the best time to do it. In our scenario, the expansion is exercised in 2021, which is one year into our purchase window. It isn’t possible to mine the additional ore material in 2020 to justify incurring the expense, so Scheduler delays the investment until 2021 when the expanded capacity can be utilized. By increasing our mill feed from 2021, we can achieve a total NPV of $3,788 million, which is an increase of more than $357 million over our original schedule.

Summary

In this how-to you have seen a quick, yet powerful way of integrating Capital Expenditure for a delayed mill expansion into your strategic mine plan. With Capex Modeling in Minemax Scheduler, you can solve far more complex Capex scenarios than we have shown today. For example, you can model several increased capacity options and see which one gives the best value. Capex modelling can be used in sizing new processing plants, or truck purchase or ramp-up – the options are countless.

If you’d like to discuss how to use Capex modelling in your specific situation, contact one of our mining engineers who are always ready to help.