As a strategic mine planner, you often deal with the requirement to move enough waste material to build mining infrastructure before other activities can begin. To satisfy this, you may need to put in many constraints to get a schedule that meets your objectives: limit this pit in a certain period, force another pit to be mined in another period. But this bottom-up process often leads to unnecessarily high upfront costs, resulting in a lower NPV. This is because adding more constraints to your model leaves less room for the optimization to do its job to find the best possible schedule.

So what’s the solution to micro-managing your schedule?

A New Type of Constraint

The good news is that there is a new type of constraint – cumulative constraints – available in Minemax Scheduler so you can minimize upfront costs while achieving a just-in-time satisfaction of infrastructure constraints requiring waste material. In this short article we’ll explain the benefits of cumulative constraints using a sample model of a Copper mine.

The Copper Mine Example

For this example, we assume an operating mill with a waste dump and a tailings storage dam that is filled to capacity by the end of the third year of the mining operation. An additional tailings storage dam will be needed from that point, so our plan needs to provide the necessary material (waste) for constructing the additional dam.

The Traditional Approach

Let’s begin by looking at the traditional method of modelling our requirements without using cumulative constraints.

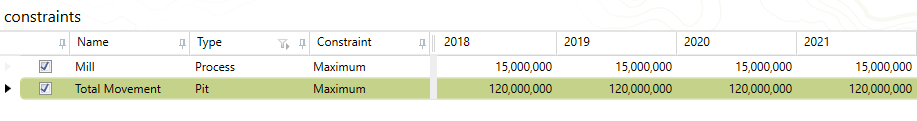

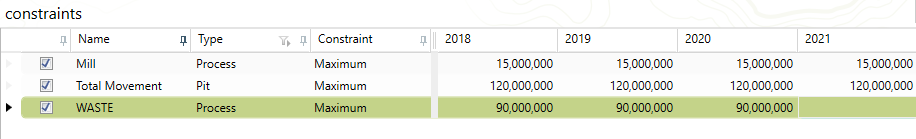

The table below shows the standard processing and mining constraints used to model the mill feed (15 million per year) and the total material movement (120 million per year).

To provide the resources to build the additional tailings storage dam, we have to move a minimum of 270 million waste tonnes within the first three years (2018 – 2020). In the traditional approach, one way is to divide this total amount into three equal amounts for the first three periods of the schedule (2018, 2019, 2020) and set this constraint as a minimum (min 90 million per year).

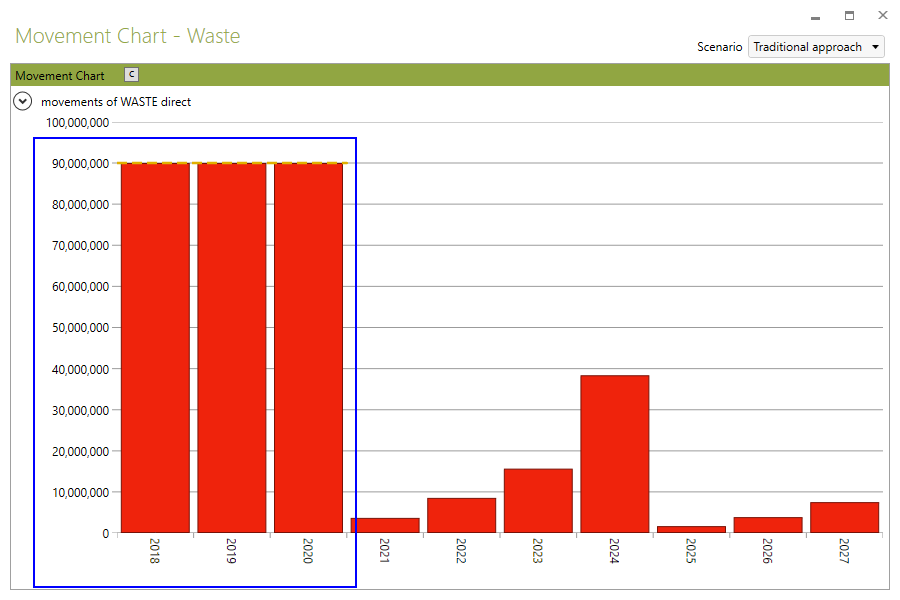

As we can see in the chart below, the primary requirement of moving 270 million tonnes of waste material by 2020 is satisfied by mining the minimum amount of waste material defined (90 million per year).

However, the issue with this approach is that we are forcing the software to mine equal amounts of waste material in each period from 2018-2020, which may not produce the best possible schedule. To find out if this is the case, we would need to re-run the scenario with different combinations and compare the NPVs for each scenario. There’s no doubt that such an approach would be very time-consuming.

The New Approach with Cumulative Constraints

Now let’s use the new approach with cumulative constraints. With Minemax Scheduler, we’re now able to put maximum or minimum limits on cumulative values. This makes it possible to constrain the total amount of waste material moved by 2020, while having the freedom to fluctuate in individual periods. This allows our optimization technology to find the best possible schedule given our real constraint requirements.

It’s very easy to do this in Minemax Scheduler:

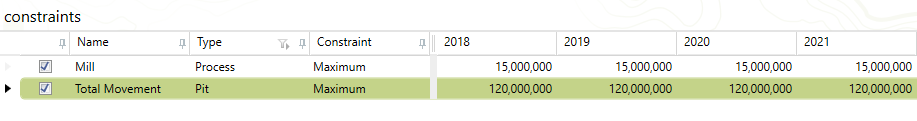

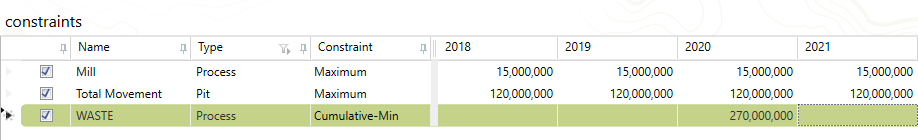

STEP 1. First we go to scenario > constraints and constrain the mill feed (15 million per year) and the total material movement (120 million per year) as we did in the traditional approach.

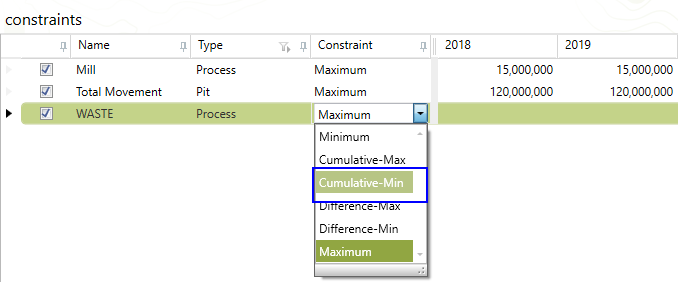

STEP 2. Next we add the Waste process to the constraints table and select the new Cumulative-Min type from the drop-down menu.

STEP 3. Then we enter the value of 270 million waste tonnes in time period 2020 to ensure the total amount of waste material is moved by 2020.

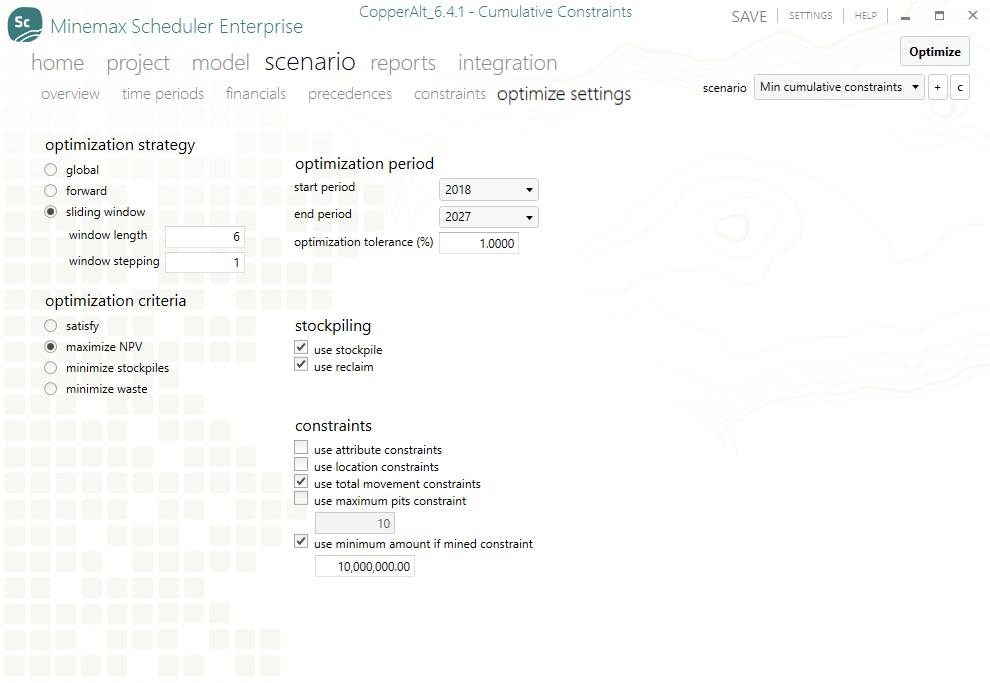

STEP 4. Next we go to scenario > optimize settings and click the Optimize button to generate a schedule that maximizes the NPV while meeting all constraints.

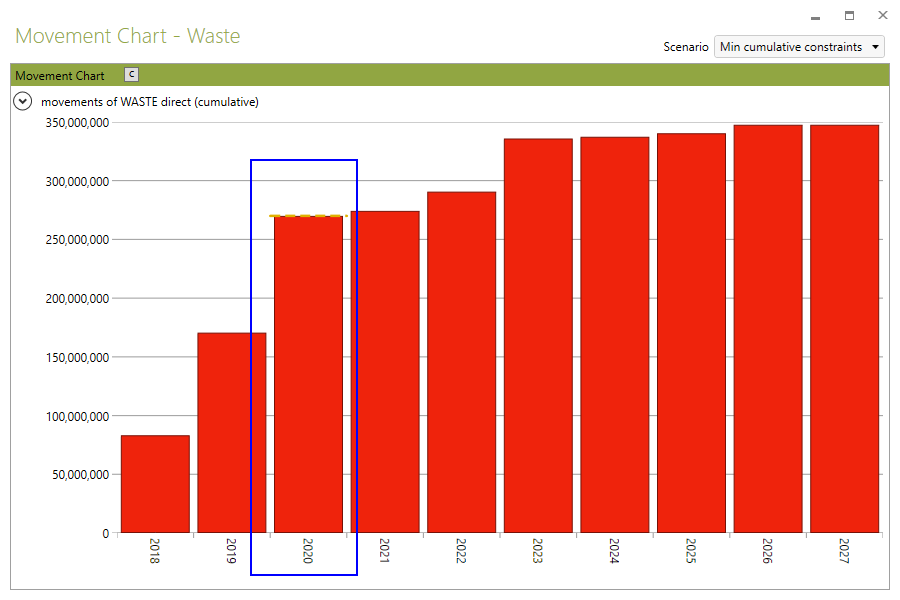

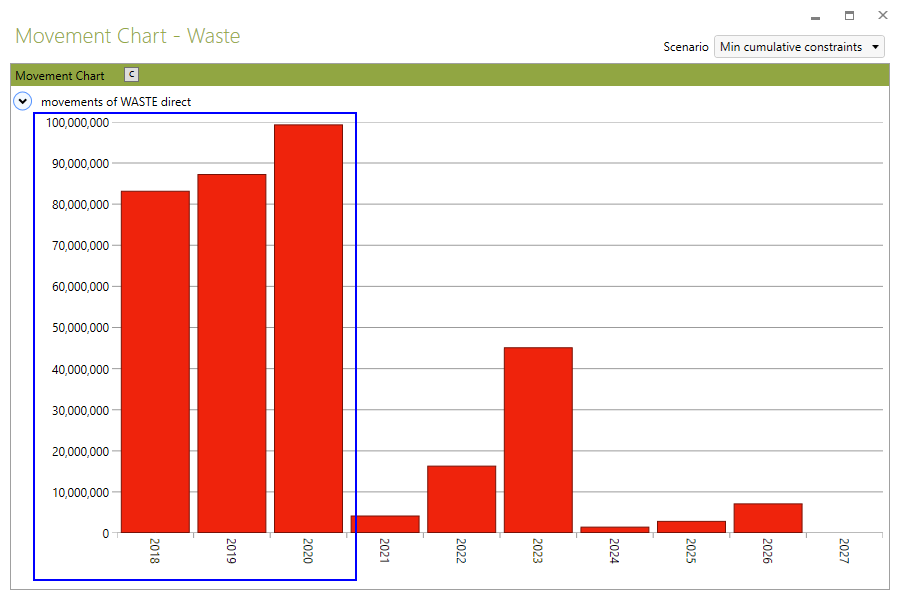

STEP 5. Finally we go to reports > movement chart and select the Waste process displayed in cumulative values. We can see in the chart below that the cumulative constraint of 270 milion waste tonnes is satisfied by 2020.

STEP 6. In the same chart, we choose the normal option from the summation drop-down to display standard values for individual waste movements instead of cumulative values. This shows us that Minemax Scheduler decided to mine varying quantities (83.3 million waste tonnes in 2018, 87.3 million in 2019, and 99.4 million in 2020) to produce the schedule with the greatest value.

Traditional vs. Cumulative Approach Results

Finally, let’s look at the financial results for both approaches to see how upfront costs and total NPV values compare for both scenarios.

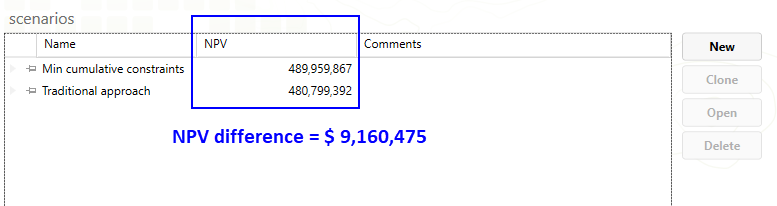

In the scenario comparison below, we can see that the schedule using cumulative constraints achieved a greater NPV than the traditional approach using standard constraints. The difference in the strategic value is more than $9.1 million.

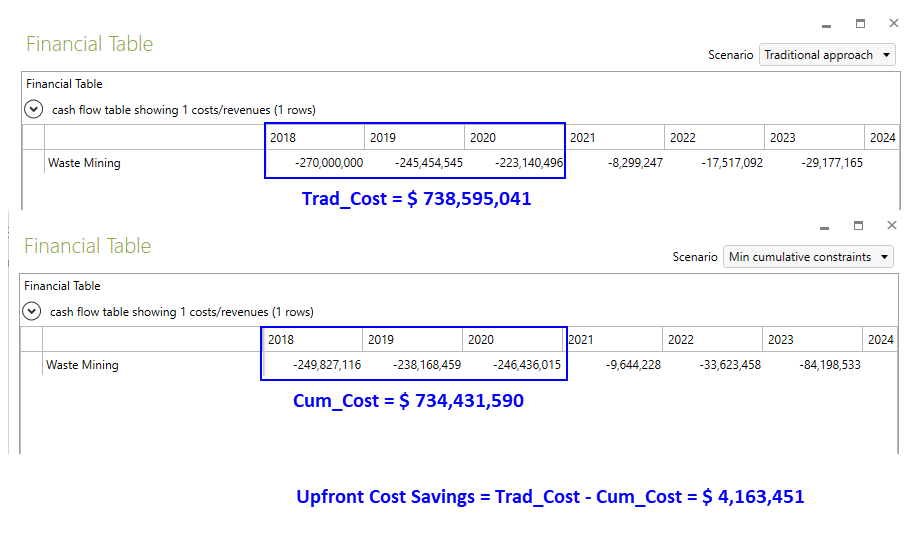

In the Financial Table below, we can also see that the upfront costs in the first three years of the schedule are lower for the scenario with cumulative constraints, leaving us with an upfront cost savings of more than $4 million.

Summary

In this article, you have seen how easy it is to model cumulative constraints in Minemax Scheduler to control the total amount of material moved by a given time. The results clearly show that the scenario using cumulative constraints produces a schedule with a greater NPV and with lower upfront costs than the schedule using the traditional approach. This is because with cumulative constraints, we are able to model multiple constraint requirements in a more flexible way, giving Minemax Scheduler more scope to optimize the schedule.

This example explains only one of the many applications of cumulative constraints in strategic planning. Our mining engineers would be happy to hear about your particular requirements and talk you through how to use this type of constraint to optimize your schedule.