We all know that in today’s competitive global economy, businesses must deliver better results using fewer resources in order to survive.

This climate appears to be accelerating, not abating, and so most of us accept it as a significant part of our job. We must figure out how to do more with less, and simultaneously enhance our competitiveness.

Mining organizations are not immune to this challenge; we must find higher project net present values (NPVs) in tighter planning horizons as compared to days gone by.

Fortunately, mine scheduling is one area where better results can be achieved with existing technology.

Challenges to Finding the “Best” Schedule

The objective in mine scheduling is to find the best possible schedule, sometimes in the presence of complex, conflicting requirements. “Best” can be anything that lines up with an organization’s business objective. Normally it is Net Present Value (NPV).

A challenge is to find better quality (higher NPV) schedules with less planning effort. We assume that identifying and evaluating more schedules increases the likelihood of finding a better schedule, yet it requires more of our time.

So should we take time from other tasks to find better schedules, or should we settle for any suitable schedule and then move on to our other tasks?

Either way, once we determine the final schedule, we still have a lingering concern that we haven’t found the best schedule.

Optimization technology is capable of addressing the challenges of finding higher NPV schedules with less planning effort.

What is optimal?

The terms “optimal” and “optimization” are often used but not always correctly understood or applied. Let’s clarify the real meaning of these terms before proceeding.

In general, both words focus on problem solutions – mine schedules in the context of this article. “Optimal” means the “best” solution, while “optimization” is the approach taken to find the optimal solution.

We know that optimal means “best”, but how can we be certain that our schedule is optimal? To know that a schedule is truly optimal, we must prove that no other better schedule exists. We can do this by evaluating every possible schedule that satisfies the operational requirements.

However, the large number of potential schedules makes this task impossible without the use of a computer-based mathematical modelling approach. Optimization is this approach, intelligently searching through all feasible schedules, and providing us with the guarantee that no better schedule exists.

Optimization is the approach for finding the optimal solution and providing us with the guarantee that no better schedule exists.

Approaches to Finding the “Best” Schedule

Without optimization, what does searching for the best schedule look like?

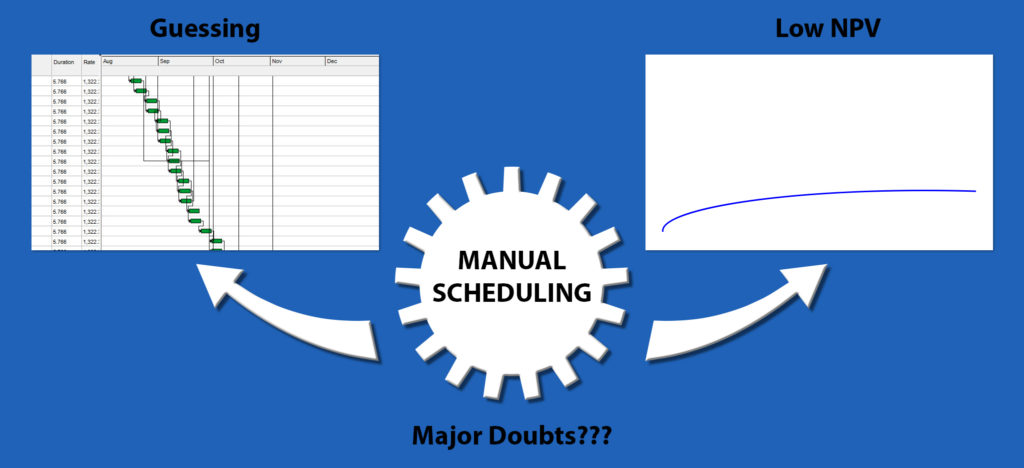

The Manual Approach

When we search for the best schedule manually, we typically use spreadsheets and follow these steps:

- We create schedules that we believe should produce good results

- We evaluate those schedules by calculating a value (e.g., NPV) for each of them

- We choose the schedule with the highest value.

Drawbacks of the Manual Approach

- This process can be laborious, as satisfying competing constraints can be difficult, especially when meeting blending requirements or developing multiple material-routing scenarios

- There is a risk that we will miss out on evaluating many potential schedules

- Our solution is limited to the possible schedules created in the first step; we can only evaluate those that have been created

- Evaluating large numbers of schedules takes a lot of time

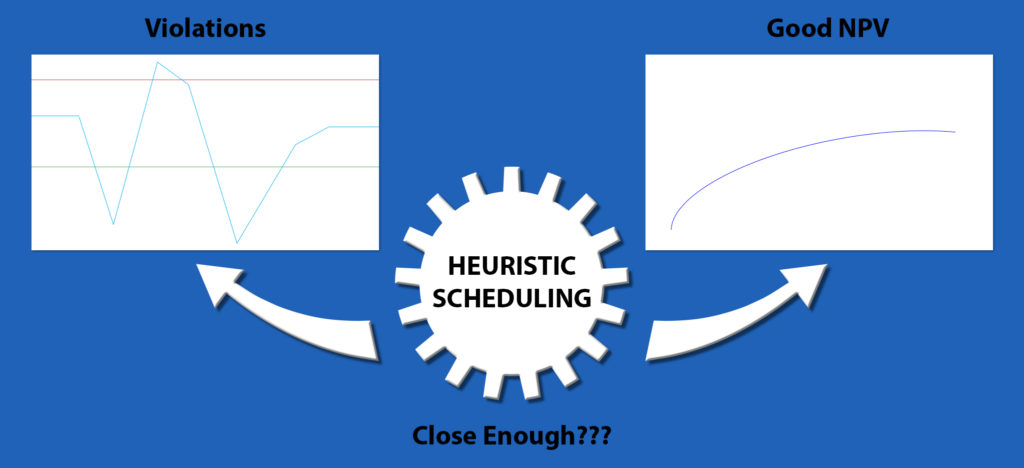

The Automated (Heuristic) Approach

A better method is to search for the best schedule using an automated computer-based approach for generating and evaluating schedules. This is typically a heuristic method employing these steps:

- We create a set of rules and logic which characterize what a best schedule should look like

- The heuristic generates and evaluates schedules based on our rules and logic

- Our computer quickly produces schedules that we may not have even considered, reducing the chance that the best schedule is overlooked

Drawbacks of the Heuristic Approach

- There is no guarantee that the schedule will satisfy complex constraints (e.g., blending)

- There is a risk that the truly optimal schedule has not been found

- We still may have to manually envision different sets of rules and logic to create and solve different model variations, in order to ensure the heuristic evaluates a sufficient number of potential schedules.

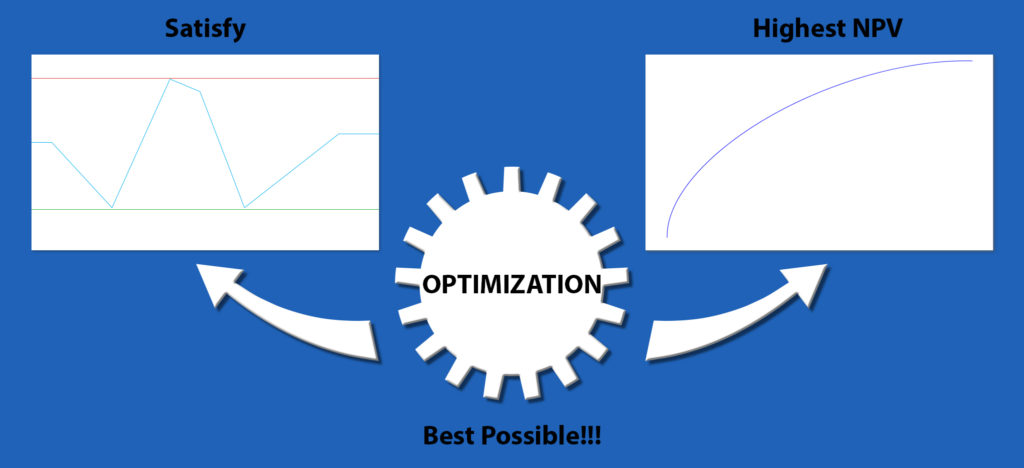

The Preferred Approach to Finding the Optimal Schedule

If our aim is to find the provably best schedule and minimize the hours required to find it, schedule optimization is the preferred approach to take.

Why optimization is the best approach

- We input model parameters and requirements for our project, and the modelling software builds a mathematical model

- The optimizer uses this model to sort through all feasible schedules

- The optimizer chooses the optimal schedule with a guarantee that no better schedule exists

Tying it together using a mining analogy

We can think of manual, heuristic and optimized scheduling approaches in terms of physical mining operations.

Manual scheduling is like excavating your entire pit with a single miner digging with a spade. The engineer searches for the best schedule, one schedule at a time.

Heuristic scheduling is similar to excavating with a modern shovel, but without knowing the limits of the deposit. The engineer’s heuristic searches through many schedules, but there is no guarantee that the best schedule won’t remain unexamined.

Optimized scheduling is analogous to how modern, efficient mining operations are executed, utilizing the best equipment within the defined limits of the deposit. The optimizer searches through all possible schedules, with the guarantee that no potentially valuable schedule will remain unevaluated.

Embracing optimization is the key to your mining organization’s survival

Knowing that optimization finds the truly optimal solution, you can use your time on other important tasks such as thinking, planning and analyzing the results.

As margins decrease and competition increases, mining companies are looking for a lifeline. Those who successfully embrace and leverage technologies will survive and thrive, and those who don’t will be left behind.

For decades successful miners have enjoyed a competitive advantage by using optimization. Today, that advantage has become a necessity, and is why the top performing mining companies include optimized scheduling along with other cutting-edge technologies.

Will optimization be your lifeline to surviving in today’s economy, enabling you to do more with less, while simultaneously enhancing your competitiveness?

Follow through

For more in-depth details on how optimization is used throughout the mine planning process to guarantee top results, download our white paper Strategic Mine Schedule Optimization.