A typical block model provided by a geologist can have millions to hundreds of millions of blocks. This is great if you like detail, but not every process in mine planning and scheduling needs that much detail. In fact, many processes are not able to handle that many blocks.

So how do you reduce the number of blocks in your model, and how do you do it quickly, easily, and safely?

Enter the Reblocking

When modelling a mine, the standard representation of the available material is a block model: a regularised 3D grid where each grid cell (or block) has a number of recorded properties. These properties are the quantities and qualities of the material within that block. As you know, for a large ore body and the surrounding waste, this can mean a very large number of blocks.

One way to reduce the number of blocks in an existing block model is reblocking. This is a technique that aggregates some blocks together into larger blocks. The new blocks are the weighted sum of the original blocks that they represent. Two common forms of reblocking are geometric reblocking, and attribute-based reblocking. Each has advantages and disadvantages, so let’s look at these reblocking options in a little more detail.

Geometric Reblocking

Given that material within a block model is already aggregated into abstract blocks, the simplest way to reduce the number of blocks is simply to make those blocks bigger. By merging neighbouring blocks together, we can do this without going back to the original statistical model. Material within these blocks is aggregated together by adding quantities, and blending attributes (weighted by quantity).

We must take care when merging blocks to consider material from each pushback separately, so as to avoid situations where a block could belong to multiple pushbacks.

Advantages

- The original geometric structure of the model is retained

- Block merging can be controlled in each dimension (easting, northing, bench) to get the exact block size and count required

- Estimating the resulting number of blocks is easy

Disadvantages

- Any fine details (such as thin veins or ore) are lost, as high-grade blocks are smoothed out and aggregated into neighbouring lower grade material

- Reducing the number of blocks too far will result in very large, very average-grade (and potentially unprofitable) blocks

- Blocks at pushback boundaries may overlap each other, and so are not strictly geometrically correct

Attribute-Based Reblocking

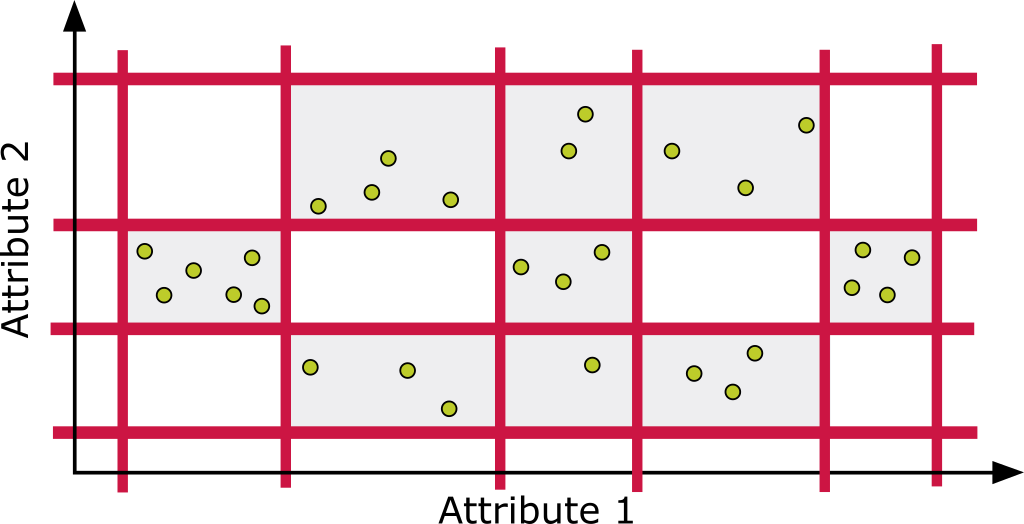

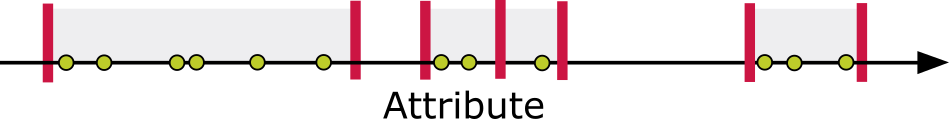

Where geometric reblocking merges geospatially neighbouring blocks, attribute-based reblocking merges attribute-neighbouring blocks. In the simplest case, we choose a single attribute (typically the most important attribute, such as the primary grade) and subdivide the range of this attribute into a number of sub-ranges or “bins”. Reblocking examines each block within the same pushback and bench for the value of the chosen attribute, and chooses the appropriate bin for each. Once reblocking has examined the complete set of blocks, it aggregates all blocks that are put into a bin.

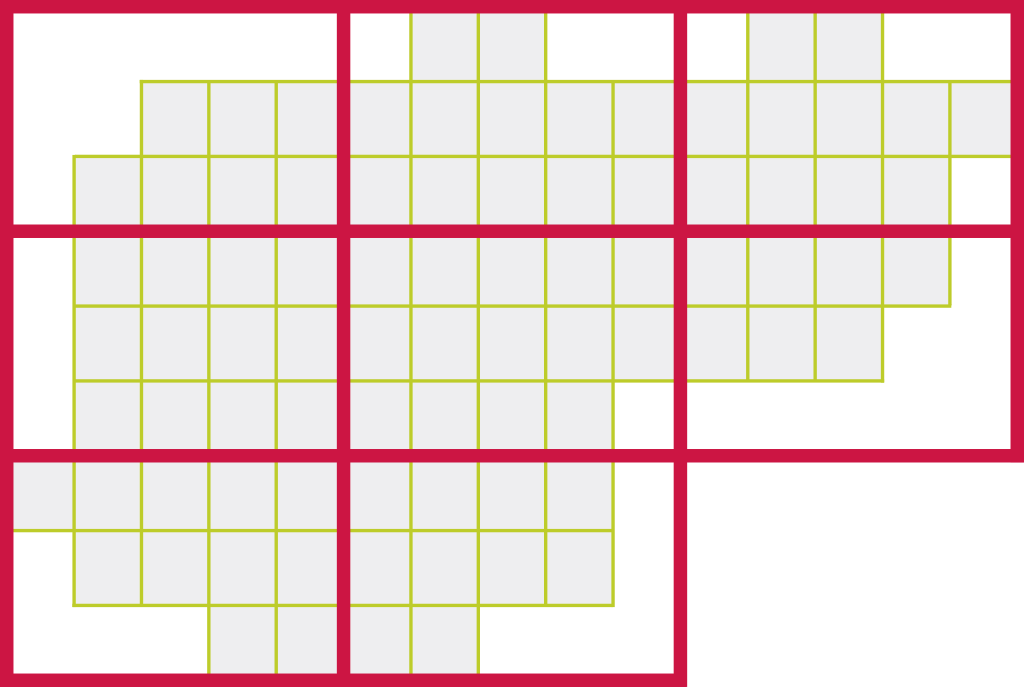

There is typically no reason to have multiple blocks if all of the material is sent to the same destination, and the qualities of the material have no bearing on constraints or financial results. Therefore, we can use a single bin for attribute values that have little distinction (such as waste material). For material with attribute values that impact decisions more closely, such as those close to cut-off grades or for critical contaminants, we can use smaller bins. If the model has more than one important attribute – such as in a multimetallic deposit – reblocking can be performed for multiple attributes. In this case, we specify ranges for each of the important attributes. We then combine these ranges and create a multidimensional partitioning of bins. As before, reblocking places each block in a single bin, but now that bin is determined by the values of each of the important attributes.

Advantages

- The block count can be reduced significantly, while controlling which materials are aggregated

Disadvantages

- All geometry within the bench is lost (so scheduling should no longer be performed at the block level)

- Bad choices for binning ranges can lead to grade smoothing, or aggregation of material that should remain separable

- It is sometimes difficult to estimate the resulting number of blocks, as the number of utilised bins on each bench is not known in advance

Everything Simplified

Reblocking is an easy way to simplify your model. Geometric reblocking is useful if you need to maintain the geometric structure of the model, while attribute-based reblocking is useful if you need to maintain value specificity. We’ll be talking more about the impact that reblocking can have on schedule optimization in a future article. We’d be happy to talk to you about how you can use reblocking to get more value out of your strategic mine plan – just ask!